SiSiC

Properties & Application Areas

Silicon Carbide is the Outstanding Choice of High-Performance Materials

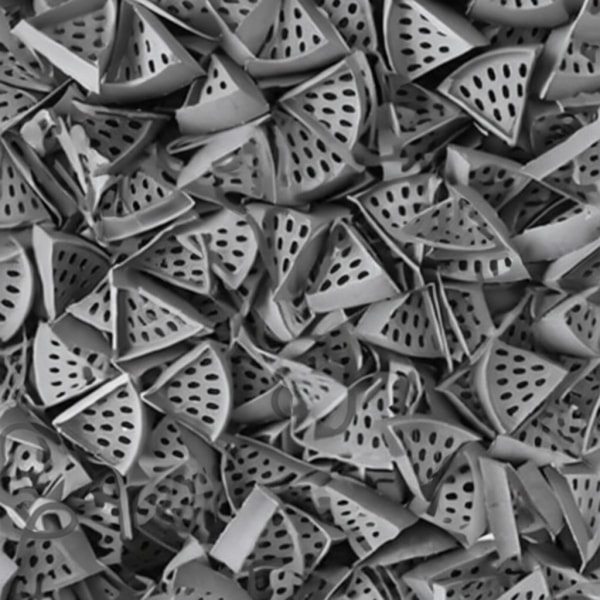

Silicon carbide possesses remarkable performance characteristics. It has an extremely high hardness and strong wear resistance. Its thermal conductivity is high, endowing it with excellent heat dissipation performance. Moreover, it exhibits good chemical stability and is resistant to corrosion.

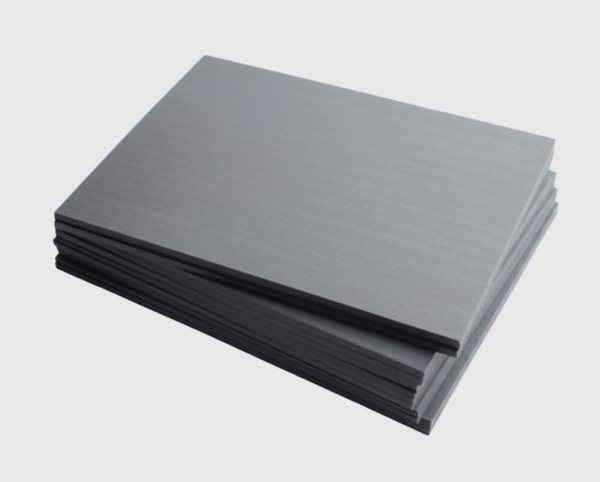

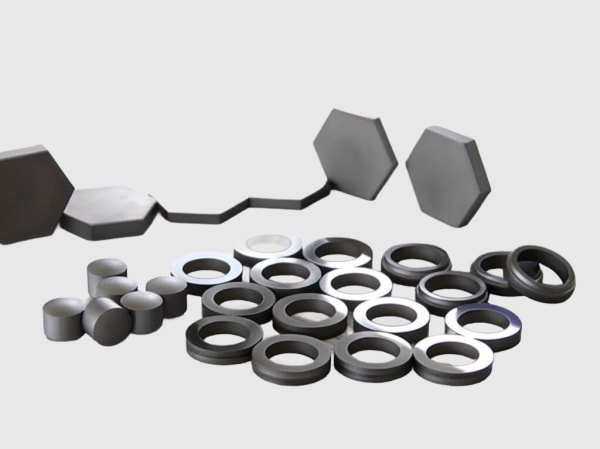

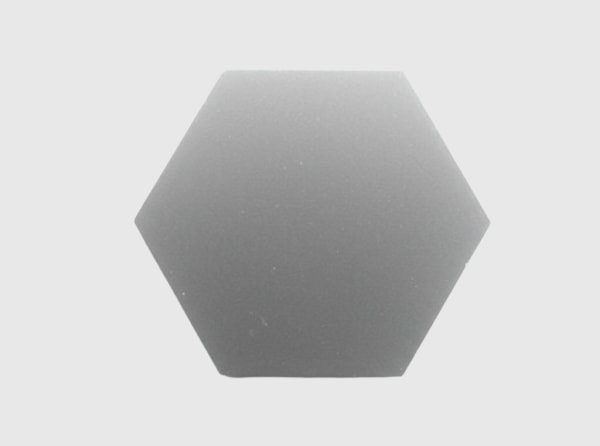

SiSiC

Siliconized Silicon Carbide

SiSiC is a high-performance ceramic material produced through a chemical reaction sintering process. It has become a critical material in aerospace, energy, electronics, and chemical industries, particularly for high-reliability applications under extreme conditions. Its properties and application areas are as follows:

Properties

High Strength and Hardness

Second only to diamond and cubic boron nitride in hardness, it offers excellent wear resistance, making it suitable for high-load working conditions.

High-Temperature Resistance

Capable of long-term use at temperatures exceeding 1600°C, with strong thermal shock resistance to withstand drastic temperature changes.

Corrosion and Oxidation Resistance

Exhibits superior resistance to acids, alkalis, salts, and molten metals, along with outstanding oxidation resistance.

Low Thermal Expansion Coefficient

Features low thermal expansion and dimensional stability, ideal for precision mechanical components.

High Thermal Conductivity

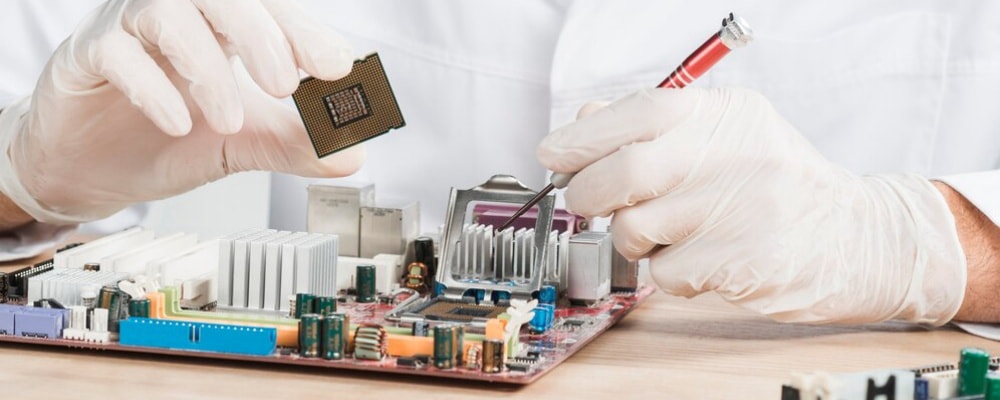

Thermal conductivity approaching that of metals ensures efficient heat dissipation, suitable for electronic device cooling.

Application Areas

Mechanical Engineering

Chemical and Environmental Protection

Electronics and Semiconductors

Energy and Environmental Protection

Industrial Manufacturing

Product Examples

Customize Your Parts Today!

We possess the wide-ranging technologies for customizing silicon carbide products, such as material technology, processing technology, design technology, and integrated process technology from materials to products. Therefore, we are capable of handling various customization requirements. If you need further customizing solutions or to learn about other process types of silicon carbide products, please feel free to contact our engineering team first.