S-SiC

Properties & Application Areas

Silicon Carbide is the Outstanding Choice of High-Performance Materials

Silicon carbide possesses remarkable performance characteristics. It has an extremely high hardness and strong wear resistance. Its thermal conductivity is high, endowing it with excellent heat dissipation performance. Moreover, it exhibits good chemical stability and is resistant to corrosion.

S-SiC

Sintered Silicon Carbide

Usually, the pressureless sintering process is adopted. High-purity silicon carbide powder is mixed with a small amount of additives, and then heated to around 1800°C to 2000°C in a high-temperature furnace for sintering. A dense ceramic structure is formed through the diffusion and fusion of particles.

Properties

Extreme Hardness and Wear Resistance

High-Temperature Stability

Chemical Inertness and Corrosion Resistance

High Thermal Conductivity and Low Expansion

High Purity and Uniform Structure

Application Areas

Industrial Manufacturing & Mechanical Engineering

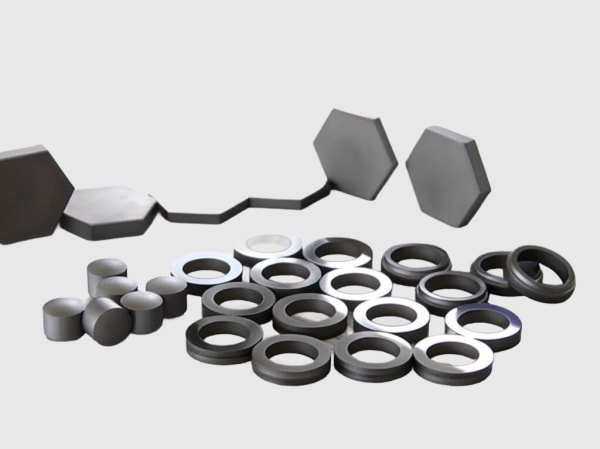

Sealing & Bearing Systems

Mechanical seals for centrifugal pumps/compressors maintain long-term stability under high pressure, temperature, and corrosive media.

Example: SSiC pump seals last 5x longer than traditional materials.

Wear-Resistant Components

Slurry pump impellers in mining and drill bit nozzles in oil drilling resist abrasive and chemical erosion.

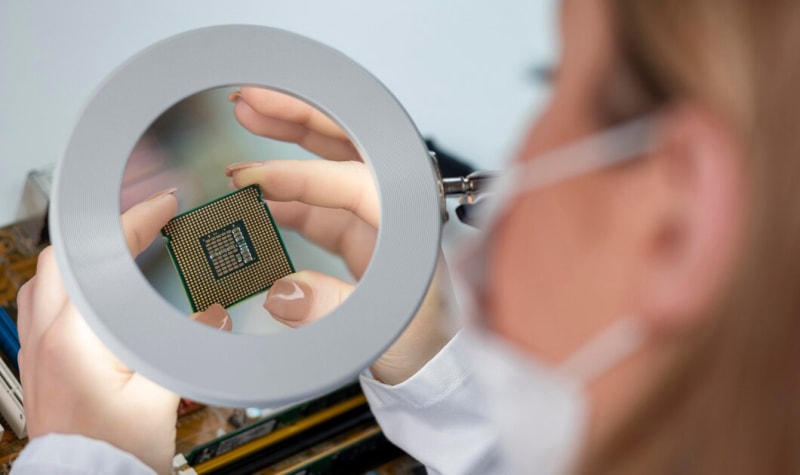

Electronics & Semiconductors

Wafer Processing Equipment

Wafer carriers and etching fixtures in semiconductor manufacturing withstand 1400°C and plasma exposure.

Example: SSiC vacuum chucks ensure nanometer-level precision during wafer processing.

Thermal Management

High-power chip packaging substrates efficiently dissipate heat to extend device lifespan.

Energy & Environmental Protection

Solar Photovoltaics

Silicon wafer cutting wheels and polysilicon reduction furnace liners resist 1600°C and corrosive gases (e.g., HCl).

Nuclear Energy

Control rod cladding and heat exchanger components in reactors resist radiation and high-temperature fission products.

Chemical & Environmental Engineering

Corrosion-Resistant Piping

Pipelines for sulfuric acid/caustic soda transport eliminate rapid metal corrosion.

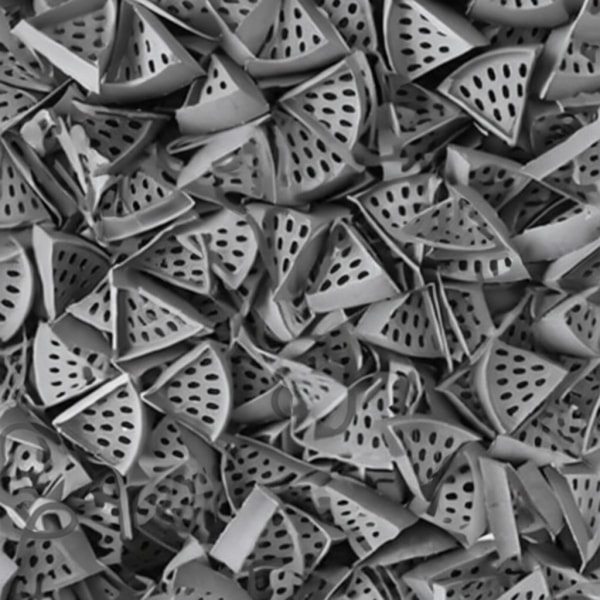

Filtration Systems

High-temperature gas purification filters for power plants/steel mills withstand 1000°C and particle abrasion.

Specialized Fields

Ballistic Armor

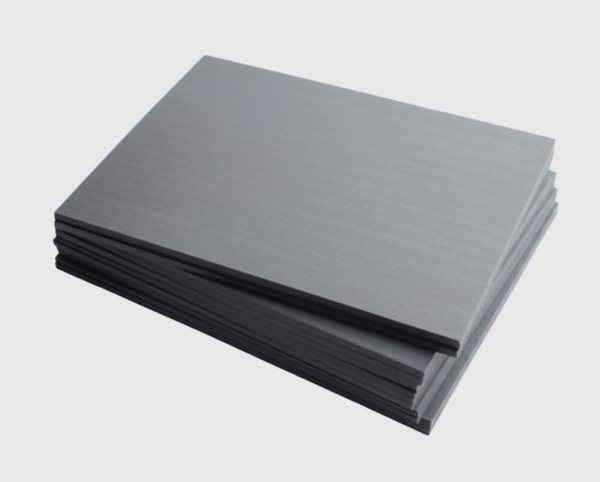

Lightweight armor plates (density: 3.1 g/cm³), lighter than aluminum but stronger, used in vehicles and personal protection.

Aerospace

Rocket engine nozzles and satellite structures maintain integrity in extreme temperatures and radiation.

Comparison of Technological Advantages

| Property | SSiC | RBSiC (Reaction-Bonded SiC) | HPSiC (Hot-Pressed SiC) |

| Purity | >99% | Contains 10-15% free silicon | >99% |

| Max Operating Temp | 1800°C (inert) | 1400°C | 1600°C |

| Cost | Moderate | Low | High |

| Typical Uses | High-temperature structures, semiconductor tools | Wear parts, kiln furniture | Precision molds, optics |

Process & Customization

SSiC is produced via pressureless sintering

High-purity SiC powder (1-10 μm) mixed with trace sintering aids (e.g., B₄C, Al₂O₃-Y₂O₃) is sintered at 1800-2150°C, forming dense structures through particle diffusion.

Customization Capabilities

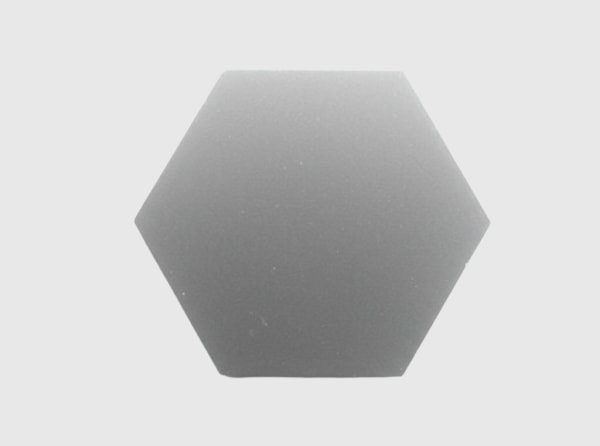

Complex shapes (e.g., helical pipes, porous filters) with ±0.05 mm dimensional accuracy.

Surface treatments (coating, lapping) for specialized needs (e.g., anti-adhesion, optical flatness).

Case Studies

Semiconductor Industry

Leading chip manufacturers use SSiC wafer fixtures, extending tool life to 10x that of traditional quartz in 200mm/300mm wafer annealing.

Electric Vehicles

SSiC inverter heat sinks improve motor efficiency by 5%, increasing EV range by 10%.

Product Examples

Customize Your Parts Today!

We possess the wide-ranging technologies for customizing silicon carbide products, such as material technology, processing technology, design technology, and integrated process technology from materials to products. Therefore, we are capable of handling various customization requirements. If you need further customizing solutions or to learn about other process types of silicon carbide products, please feel free to contact our engineering team first.