Product Example Details

Select the most suitable SiC material for your parts

Even if you are not familiar with SiC materials, as long as you tell us your usage environment and requirements, we will provide you with the most professional customization assistance.

When selecting silicon carbide materials, it is necessary to comprehensively consider the performance requirements of the application scenarios and cost factors. If cost is a sensitive factor and the performance requirements are not particularly high, RB-SIC and SiSiC may be good choices. If the performance requirements are extremely high, such as in the aerospace and high-end electronics fields, SSiC is more suitable. And for some special high-temperature thermal insulation applications, the unique performance of R-SIC makes it the preferred choice.

Selection in application of RB-SIC, SiSiC, S-SiC and R-SIC

In terms of Performance

RB-SIC

It combines the characteristics of silicon carbide and silicon, featuring high strength and hardness, good wear resistance and corrosion resistance. It has a relatively high thermal conductivity, which can meet the heat dissipation requirements to a certain extent. However, due to the presence of the silicon phase, its oxidation resistance in high-temperature oxidizing environments is relatively weak.

SiSiC

It has excellent high-temperature resistance and can maintain good mechanical properties at high temperatures. It has good oxidation resistance and corrosion resistance, and can resist the erosion of various chemical substances. In addition, it has a high hardness and strong wear resistance, making it suitable for use in wear environments.

S-SiC

With high density, it has outstanding mechanical properties, such as high strength and high hardness. It has a high thermal conductivity, which is beneficial for the rapid transfer and dissipation of heat. It has good stability at high temperatures, with prominent oxidation resistance and thermal shock resistance, and can withstand drastic temperature changes without cracking.

R-SIC

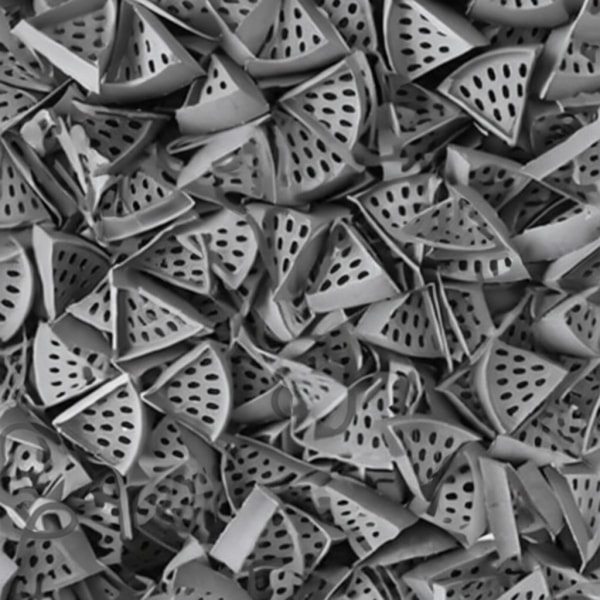

It is mainly composed of high-purity silicon carbide and has good high-temperature resistance and chemical stability. Its unique recrystallization structure endows it with a relatively high porosity, which gives it good thermal insulation performance. However, at the same time, it leads to relatively weak mechanical properties, especially in terms of bearing high pressure and high impact loads, where its performance is not as good as that of the other several types of silicon carbide.

In terms of Application Scenarios

RB-SIC

It is often used in the silicon wafer cutting fixtures in the photovoltaic industry and the wafer carriers in semiconductor manufacturing. In these applications, the strength and hardness of RB-SIC can meet the requirements for clamping and supporting silicon wafers and wafers. Meanwhile, its good wear resistance can ensure that the fixtures and carriers are not easily worn during long-term use, thus improving the processing accuracy and product quality.

SiSiC

It is widely applied in the inner linings of reaction kettles, pipelines, valves, etc. in the chemical industry. In chemical production, it often comes into contact with various corrosive media and high-temperature environments. The excellent corrosion resistance and high-temperature resistance of SiSiC enable it to operate stably for a long time, reduce the frequency of equipment maintenance and replacement, and lower the production cost. At the same time, it is also applied in cutting tools, molds, etc. in the machining field. Its high hardness and wear resistance help to extend the service life of the cutting tools and molds and improve the processing efficiency.

S-SiC

It has important applications in the hot-end components of engines in the aerospace field, blades of gas turbines, etc. Under these extreme working conditions, SSiC needs to bear complex loads such as high temperature, high pressure, and high-speed airflow scouring. Its high density, high strength, high hardness, and good thermal shock resistance enable it to work reliably and ensure the performance and reliability of engines and gas turbines. In addition, it is also applied in the heat dissipation components of high-end electronic devices. Its high thermal conductivity can quickly dissipate the heat generated by heat-generating components such as chips, ensuring the stable operation of the equipment.

R-SIC

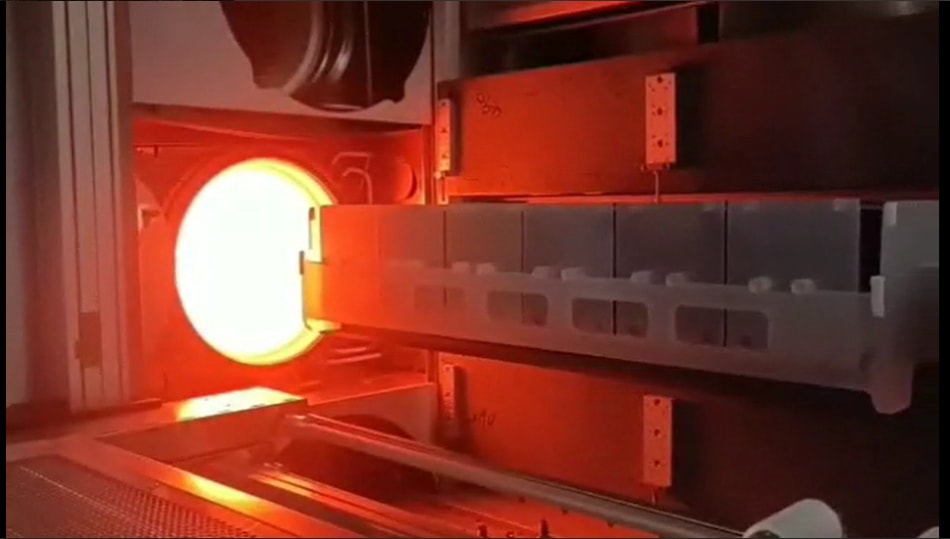

It is mainly used as thermal insulation materials for high-temperature furnaces, protective tubes for thermocouples, etc. Due to its relatively high porosity and good thermal insulation performance, it can effectively reduce the heat loss of furnaces and improve energy utilization efficiency. In the application of thermocouple protective tubes, its chemical stability and high-temperature resistance can protect the thermocouple from interference by the external environment and ensure the accuracy of temperature measurement.

In terms of Cost

| Material Type | Cost | Production Process | Application Advantage |

|---|---|---|---|

| RB-SiC (Reaction Bonded Silicon Carbide) | Relatively low | The production process is relatively simple and can be prepared at a relatively low temperature through the reaction sintering process. No need for special equipment or complex process control. | Has great advantage in application fields where cost is a sensitive factor. |

| SiSiC (Silicon Infiltrated Silicon Carbide) | Moderate | Requires certain technical and equipment support, but compared with processes such as SSiC, the cost is relatively low. | Achieves a good balance between performance and cost; widely used in many industrial fields. |

| S-SiC (Sintered Silicon Carbide) | Relatively high | Requires complex production process, high-purity raw materials, and precise process control. | Excellent performance makes it irreplaceable in high-end fields with extremely high performance requirements and low cost sensitivity. |

| R-SiC (Recrystallized Silicon Carbide) | Varies depending on process and product | Requires high-temperature treatment and special process control. Generally has relatively high cost. | Unique performance offers competitiveness in specific fields such as high-temperature thermal insulation. |

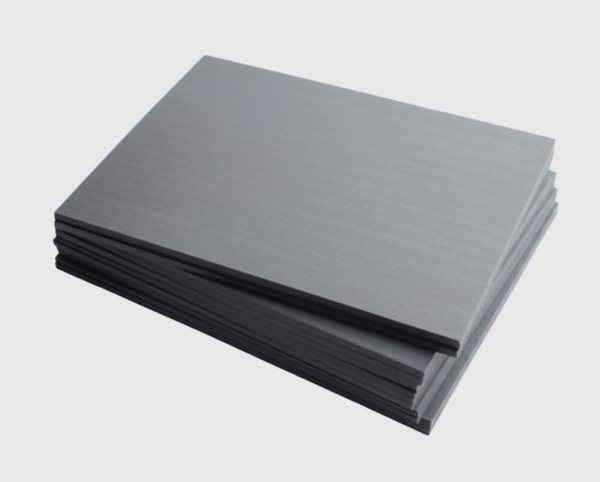

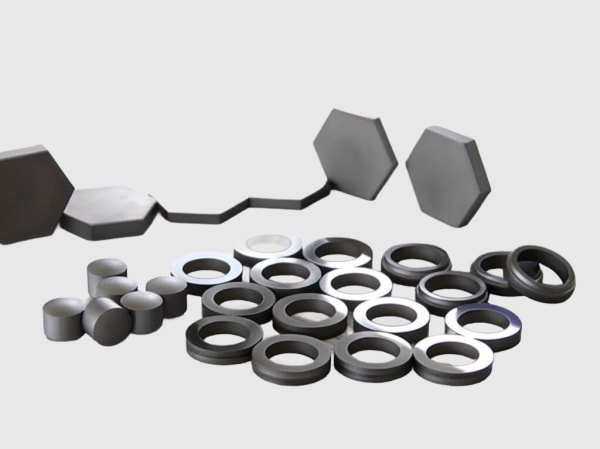

Product Examples

Customize Your Parts Today!

We possess the wide-ranging technologies for customizing silicon carbide products, such as material technology, processing technology, design technology, and integrated process technology from materials to products. Therefore, we are capable of handling various customization requirements. If you need further customizing solutions or to learn about other process types of silicon carbide products, please feel free to contact our engineering team first.