Cases

Silicon Carbide (SiC) products, leveraging their exceptional properties of high hardness, high temperature resistance, wear resistance, superior thermal conductivity, and corrosion resistance, excel in meeting performance requirements for high-temperature, high-pressure, high-frequency, and high-power scenarios. These advantages have enabled their extensive use in strategic emerging industries such as advanced manufacturing, semiconductors, new energy, aerospace, and environmental protection.

Key Application Areas of Our SicSino’s Products

Industrial Manufacturing and Processing

Abrasives and Wear-Resistant Materials

Harnessing SiC’s high Mohs hardness (9.2–9.3) and wear resistance, we produce grinding wheels, sandpapers, abrasive nozzles, and grinding balls. These are critical for precision machining—including grinding, polishing, and deburring—of materials such as stainless steel, aluminum alloys, ceramics, and glass. They are indispensable for the high-precision processing of aerospace components (e.g., turbine blades).

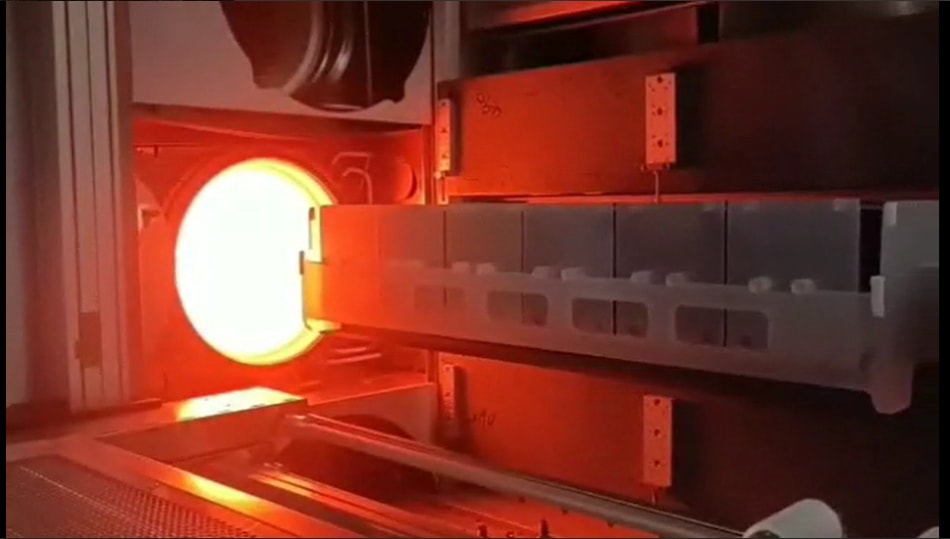

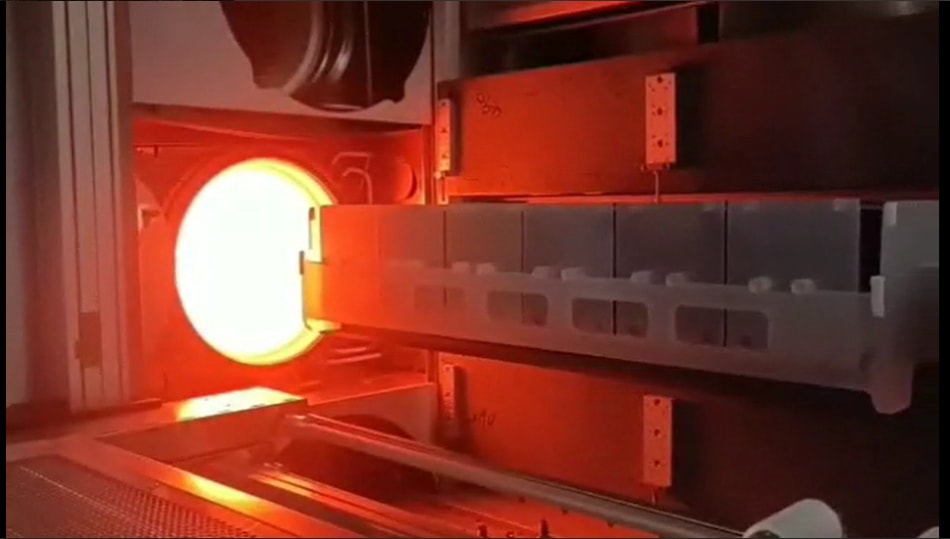

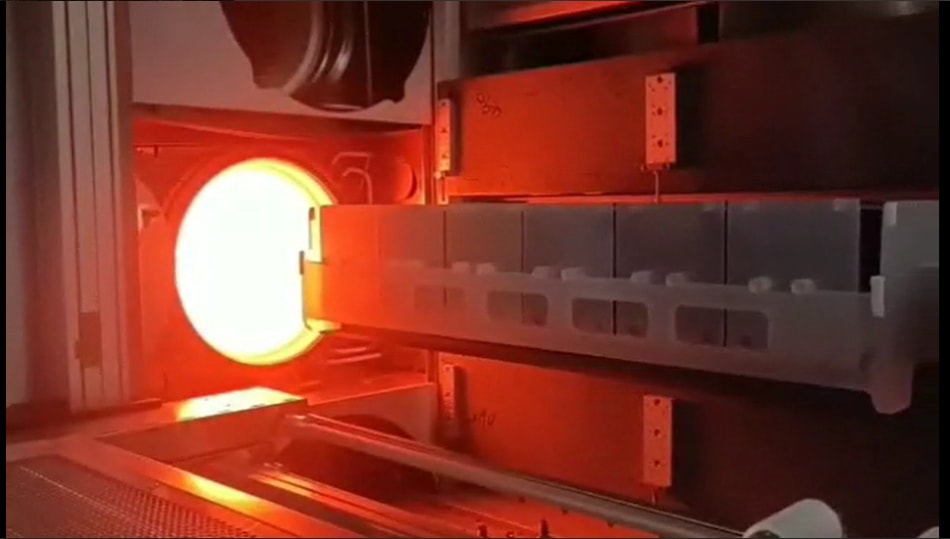

High-Temperature Structural Components

Used in high-temperature furnace parts (e.g., kiln linings, crucibles, support structures) and corrosion-resistant pipelines/reactors in metallurgy, these components withstand temperatures above 1500°C and harsh corrosive atmospheres.

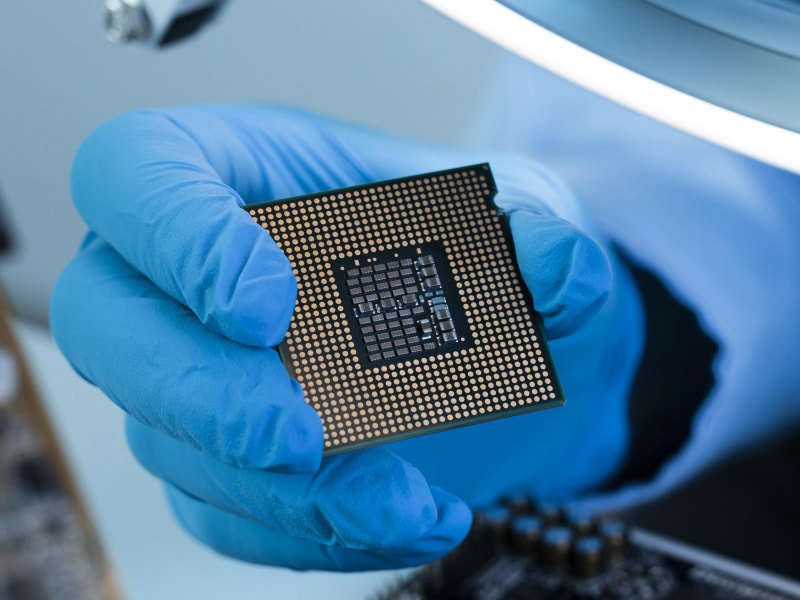

Semiconductor and Electronics Information Sector

Third-Generation Semiconductor Material

New Energy Vehicles

On-board inverters, on-board chargers (OBC), and motor controllers leverage SiC to enhance power conversion efficiency and enable miniaturization.

Photovoltaics and Energy Storage

Solar inverters and energy storage systems (e.g., lithium battery management systems) adapt to high-voltage, high-frequency operating conditions, minimizing energy losses.

Smart Grid

High-voltage power transmission equipment and power conversion modules for substations facilitate the integration of renewable energy into the grid.

Microwave and RF Devices

Used in high-frequency power amplifiers for 5G base stations and satellite communications, these devices meet stringent requirements for high-power handling and high-temperature resistance.

New Energy and Green Technology Sector

Photovoltaic Industry

As critical consumables for silicon wafer cutting and sorting (e.g., SiC wire saws and cutting fluids), SiC is used in the slicing of polycrystalline/single-crystal silicon. Additionally, SiC substrates serve as potential materials for fabricating high-efficiency photovoltaic cells.

Hydrogen Energy and Fuel Cells

SiC is applied in corrosion-resistant coatings for fuel cell bipolar plates and high-temperature resistant components in water electrolysis hydrogen production equipment.

LED Lighting

As epitaxial growth substrates for sapphire substrates, SiC enables the manufacturing of high-brightness LED chips.

Aerospace and Defense Military

Aeroengine Components

High-temperature-resistant, lightweight silicon carbide ceramic matrix composites (SiC CMCs) are used to manufacture turbine blades and combustion chamber components, enhancing engine thrust-to-weight ratio and high-temperature reliability.

Missile and Guidance Systems

SiC power devices are integrated into the high-temperature electronic circuits of missile seekers, withstanding extreme environments. Ultra-high hardness SiC armor-piercing projectile core materials enable penetration of armored targets.

Satellite and Space Equipment

Radiation-resistant SiC sensors and structural components are applied in satellite attitude control systems and deep-space exploration equipment.

Environmental Protection and Energy Efficiency

Exhaust Gas Treatment

SiC ceramic filter elements are used in diesel particulate filters (DPF) for fuel equipment, effectively filtering pollutants such as PM2.5 while withstanding high temperatures and corrosive exhaust gases.

Thermal Management Systems

High thermal conductivity SiC substrates enable heat dissipation for power modules, addressing high-density heat generation challenges in 5G equipment and data centers.

Other High-End Fields

Medical and Precision Instruments

High-precision silicon carbide (SiC) bearings are used in artificial joints and precision gyroscopes, featuring low friction and long service life.

Rail Transit

SiC devices in high-speed rail traction converters enhance energy efficiency, adapting to high-frequency start-stop cycles and high-voltage environments.

Application of SiC Accessories in Photovoltaic Power Plants