Customizing Support

Even if you are not familiar with SiC materials, as long as you tell us your usage environment and requirements, we will provide you with the most professional Customized Silicon Carbide Product Service.

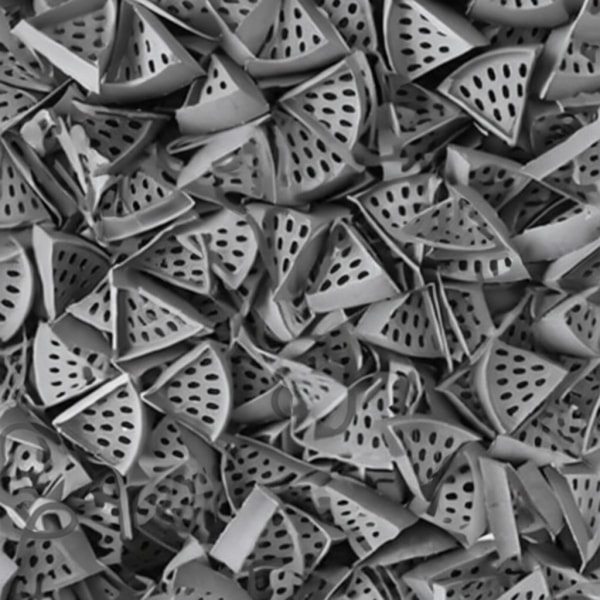

We have rich manufacturing technology and equipment, and have realized the integrated process from SiC material processing to molding, sintering, and finishing, we have rich customizing practical experience.

Clarification of the required application functions

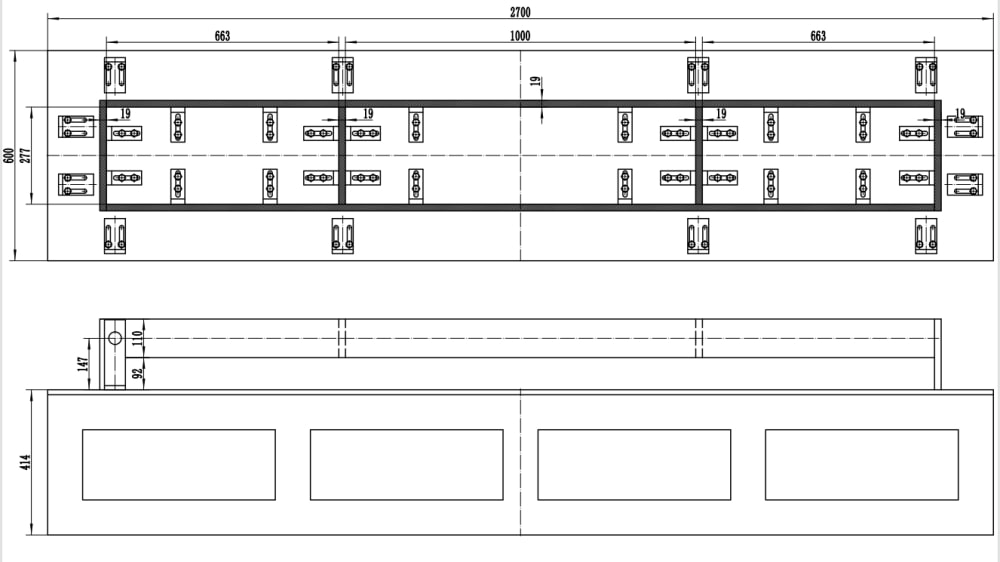

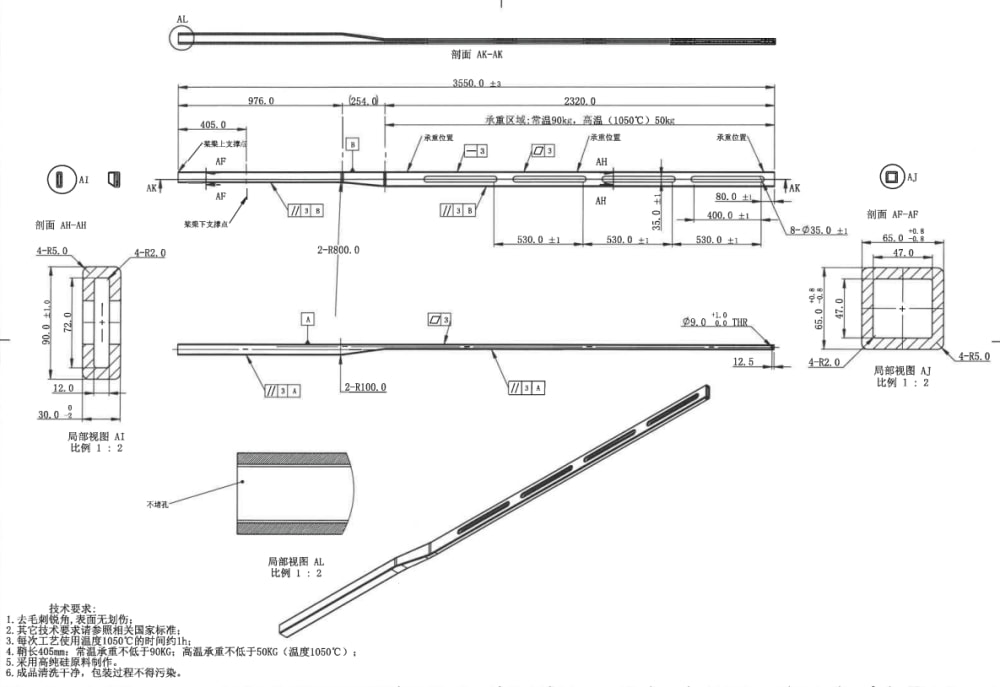

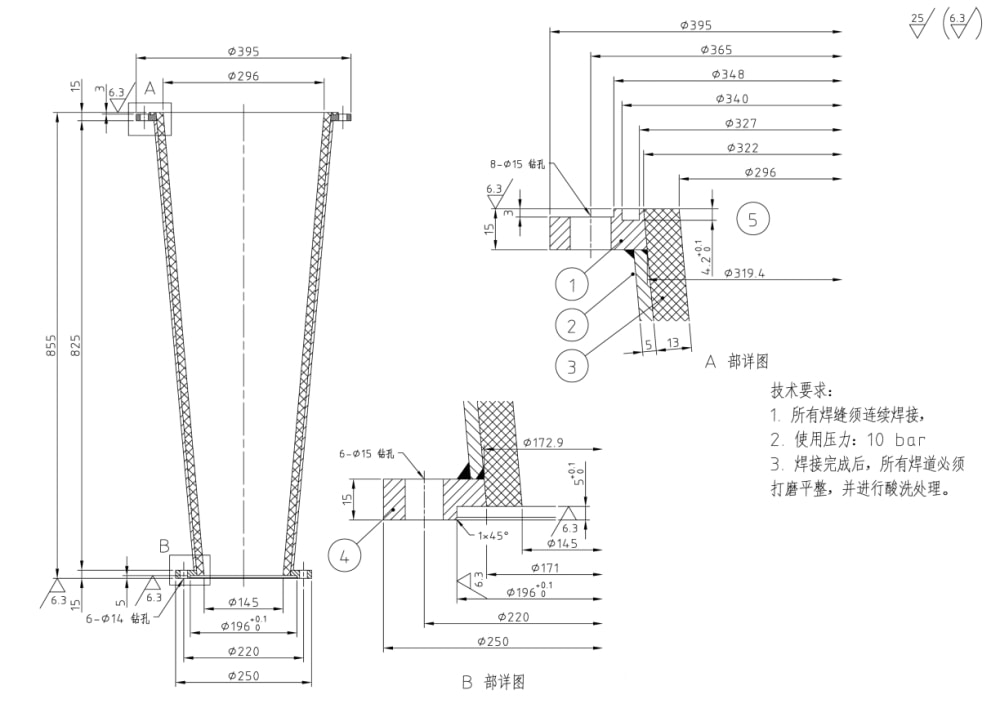

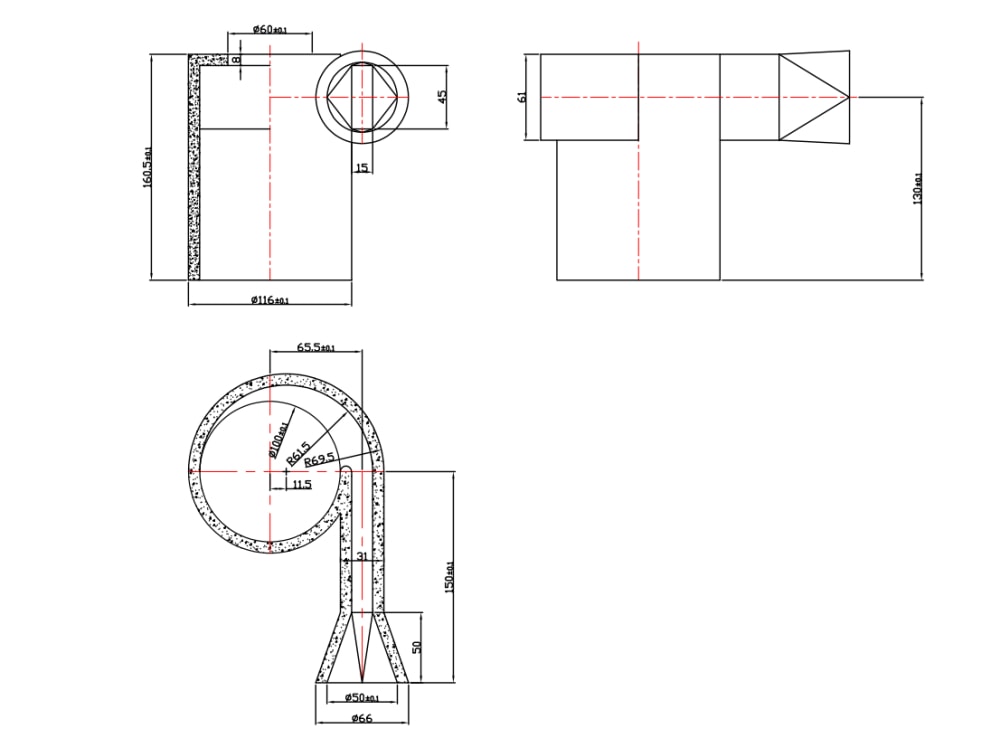

We will inquire about your interest in using SiC as a replacement for the previous parts to address the current issues. Simply let us know what features you would like the customized SiC parts to have, such as high-temperature resistance, wear resistance, corrosion resistance, etc. If you have drawings that include shape and size information, please provide them to us.

Learn about the scenarios and conditions of use

Please provide details on the intended application scenarios for the component requiring replacement, such as whether it is intended for use in the machinery, chemical, or renewable energy industries, among others. Additionally, specify the critical performance specifications needed for the part, including:

· High-temperature resistance

· Corrosion resistance

· Wear resistance

· Oxidation resistance

· Mechanical strength

· Thermal conductivity

This information will enable our engineering team to recommend the most suitable SiC grade (e.g., R-SiC, SSiC, or RBSiC, SiSiC) and optimize the design for your specific operating conditions.

Design of functionality and expected effects

pon receipt of your application details, our engineering team will conduct a detailed assessment of your operational requirements and environmental conditions. Based on this comprehensive assessment, we will recommend the most suitable SiC grade (e.g. R-SiC, SSiC, or RBSiC, SiSiC) and communicate with you several times to refine the design parameters to ensure the best performance and cost-effectiveness for your part’s specific application.

Determine the best manufacturing options

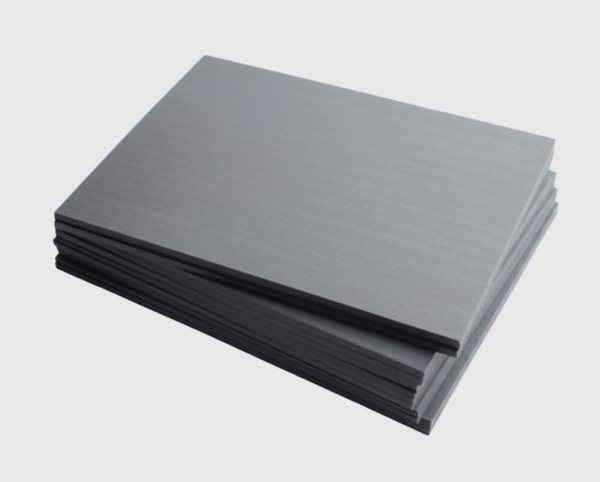

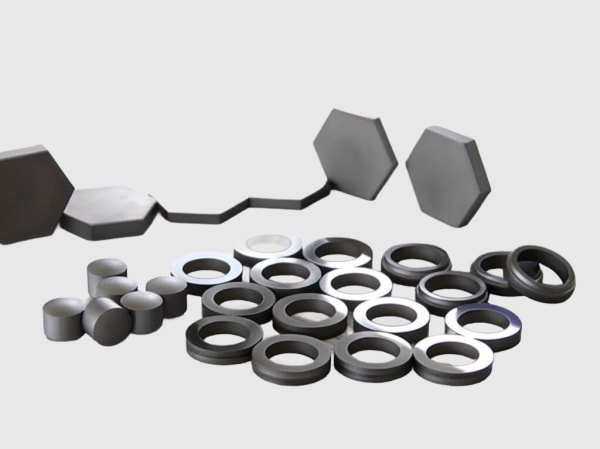

We will consider and determine the best manufacturing method from a variety of SIC molding, sintering processes, and grinding methods to ensure that your benefits, efficiency, and application meet your expectations.

Customization

We accept abnormal shaped parts, single product and small batch production requirements, as well as custom production and mass production.

We have been meeting customer requirements by utilizing a wide range of production, including miniaturization and complex shapes.