Main equipment

The processes of various types of SiC products

| Preparation of materials | → | Forming | → | High-temperature sintering | → | Post-processing Process | ||||||||||||||

| RB-SiC | ➽ | Uniform particle distribution SiC powder for the main raw material | ➽ | Dry Pressing Forming Isostatic Pressing Forming Extrusion Forming Injection Molding | ➽ | Silicon infiltration process, 1450–1800 °C. | ➽ | Grinding、Polishing Defect Inspection, Dimensional Measurement Coating, Edge Chamfering | ||||||||||||

| SiSiC | ➽ | High-purity SiC powder for the main raw material | ➽ | ➽ | Above 2000°C. | |||||||||||||||

| S-SiC | ➽ | ➽ | 2000 – 2200°C. | |||||||||||||||||

| R-SiC | ➽ | ➽ | 2200 – 2400°C. | |||||||||||||||||

Here are some basic equipment for a small RB-SiC plant:

Agitation Tanks are dedicated mixing tool for making plaster molds.

Customized agitation machines will mix raw materials such as a carbon source (e.g., graphite, polymers) and a silicon source (e.g., silicon dioxide or silicon powder) in a certain proportion, ensuring full contact between the raw materials and preparing them for subsequent reactions.

It can carry out multi-dimensional processing of various green bodies for the completed plaster molds according to the drawings.

It can perform 2D engraving on blank parts, as well as carry out operations such as grooving, drilling, and cutting on blank parts.

It is a key piece of equipment for reaction bonding (RB-SiC). In a vacuum or a specific atmospheric environment, it enables the raw materials to undergo a chemical reaction at high temperatures to produce silicon carbide.

We can customize SSiC / RSiC sintering furnaces for you according to the different use.

It can perform high-precision processing on the SiC materials sintered at low temperatures, and is used for processing complex curved surfaces, tiny holes, etc.

It is controlled by a computer, enabling precise control of the tool’s movement. It can perform various machining operations such as turning, milling, and drilling, meeting the high-precision machining requirements of SiC parts.

It is used for grinding the sintered SiC parts to improve the surface finish and dimensional accuracy of the parts.

Cleaning equipment for SiC products after the sintering process is completed.

Sclerometer

To detect the hardness of the SiC parts, determine whether it meets the design requirements, and ensure the performance and quality of the parts.

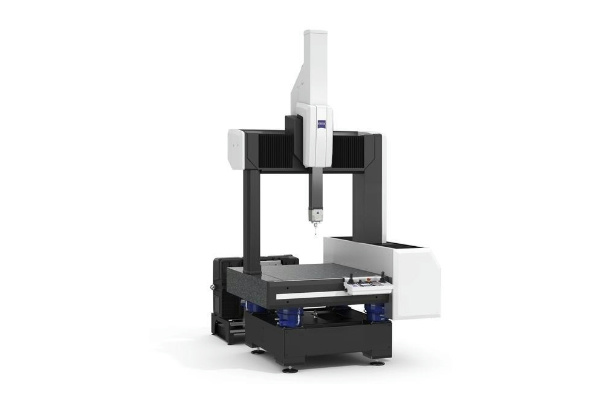

Coordinate measuring machine

To precisely measure the dimensional and geometric tolerances of the parts to provide data support for the machining accuracy, and ensure the assembly accuracy and service performance of the parts.

Air compressor

It must be equipped wherever air pressure is used, especially for Sandblasting Machine.

Standby generator set

It is used for the circulation of cooling water in case of a power outage to prevent the sintering furnace from being damaged.

Water purification equipment

The essential equipment for circulating water and cooling water of a SiC plant.